Extract! Extract! Read All About It!

It’s a complex process, requiring a lot of fancy machinery and an acute attention to detail at every step of the way. (And, lucky for you, it’s one that Insa has gotten very, very good at.) All of our extracts begin with one of two extraction processes. Which one we’ll use—either Hydrocarbon Extraction or Ethanol extraction—depends on what’s on the menu. In either case, we’ll wind up with the highest quality extracts on the market.

Step 1:

Let’s get ready to rumble!

Good concentrate comes from good flower. Lucky for us, Insa’s got the best. Hydrocarbon extraction begins with the freshest sugar leaves and buds. The fresher, more potent, and more terpene-rich the cannabis that goes into our concentrates, the more distinct—and more enjoyable—the products that come out the other side.

Step 2:

Break it down now!

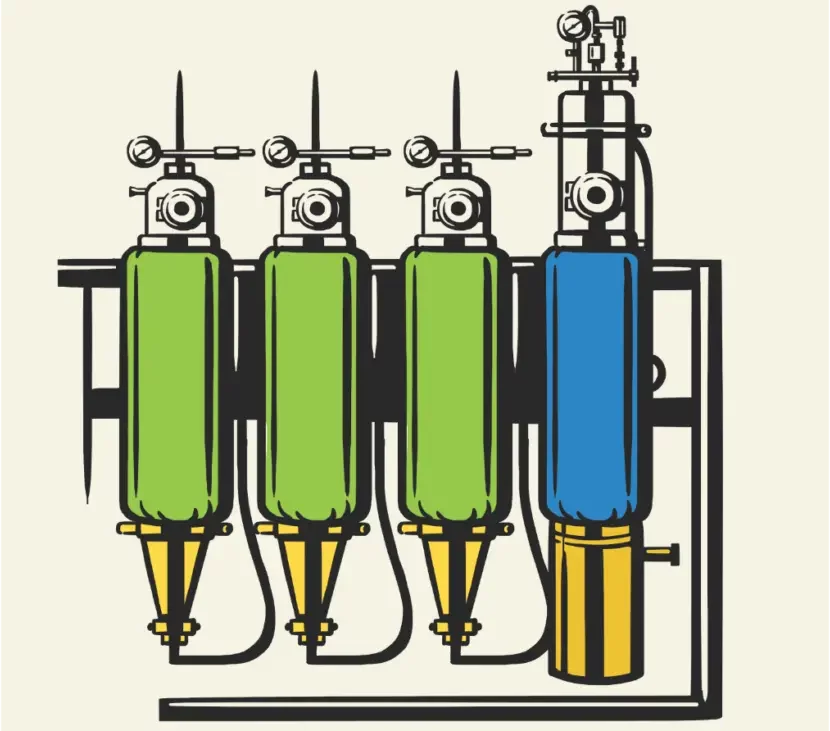

The buds and sugar leaves are loaded into columns for extraction, and then they’re washed with a solvent, which dissolves cannabinoids (including THC and CBD) as well as terpenes. Those solvents are collected in a separate tank to be reused, and what’s left drains into another collection and expansion column, where it’s ready for post-processing.

Step 3:

It’s clean-up time!

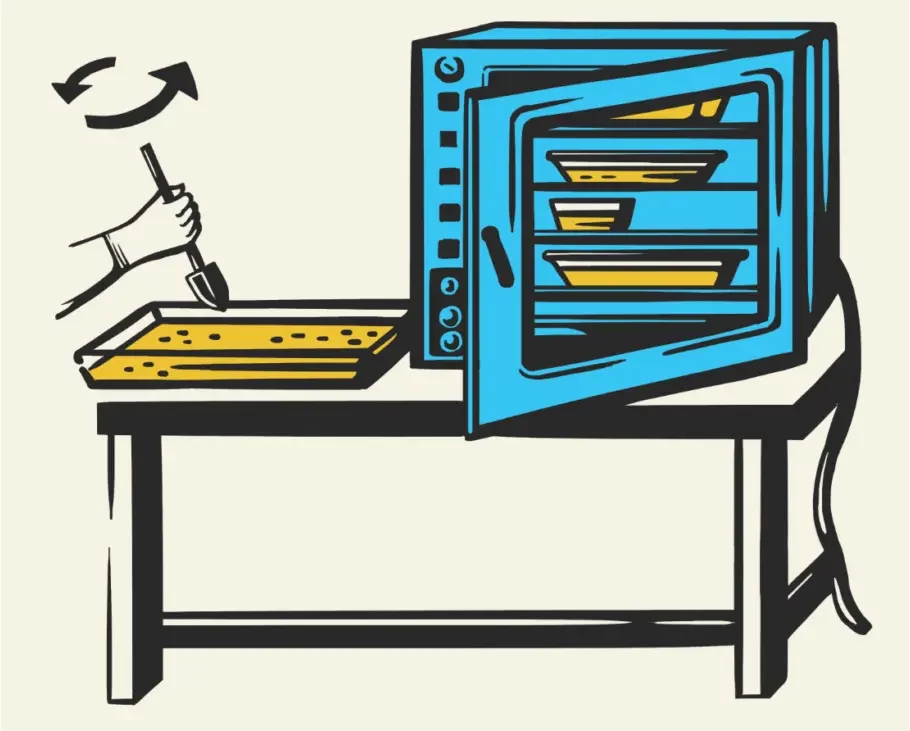

Once it’s been extracted, that solution is ready to be refined. Any remaining solvents are purged for a purer product, and then we’ll whip, vacuum, heat, pour, melt the good stuff that’s left to create our various concentrates. In every case, these extracts retain the cannabinoid and terpene profiles of the strain they were made from.

Step 1:

It starts at the very beginning!

Ethanol extraction, like hydrocarbon extraction, relies on high-quality materials for high-quality products. Because our distillates are tasteless, highly potent products, we’re able to use more of the plant than for our concentrates. No part of the plant is wasted.

Step 2:

Getting to the heart of the matter!

Plant matter is saturated with ethanol at -40 below 0. (Yeah, that’s cold.) The mixture is then agitated slightly, which helps to make sure material is fully extracted. At that point, the ethanol drains off, and we run a spin cycle like the one your washing machine does to get rid of any leftovers.

Step 3:

Scrub a bud bud!

In the roto evaporator, that extracted cannabis slurry becomes crude oil, which then goes through a decarboxylation reaction. It sounds very technical (and it is), but the result is some of the purest distillate on the market.

Step 4:

It’s almost glowtime!

That crude oil is then further distilled to create—you guessed it—distillate. It’s flavorless and very, very potent, and we blend it to produce consistent, predictable effects in our vape products, edibles, and some tinctures and topicals.

MERCH STORE

Follow INSA:

Copyright © 2025 INSA. All Rights Reserved.

Help us personalize your store experience by selecting your state.